There are things in life that are simply taken for granted. And precisely because they are taken for granted, we are all too often inclined to forget them.

Applied to boats, the blower seems to be one of the utensils that repeatedly suffer such a fate. Of course! Lonely and alone, it ekes out its existence somewhere in the furthest corners of the engine compartment. Far away from the glitz and glamor of a chic (albeit comparatively pointless) underwater light on the rear-view mirror. Only a discreet switch somewhere in the cockpit reminds us of its meagre existence.

And so it is not uncommon to come across reports or videos on social networks or YouTube at regular intervals in which the owner hastily gets behind the wheel after refueling and then blows up his beloved boat with a quick turn of the starting key.

What blowers are for

Unfortunately, in addition to rusty drinks cans and worn-out fenders, fuel vapors also collect in the engine compartment of a boat, which in the case of petrol-powered engines have the unpleasant property of forming a highly explosive mixture in combination with the oxygen in the air.

If you add to this an ignition source such as a small spark from the starter or the alternator, the disaster is of course perfect.

To prevent this, all relevant regulations such as the Recreational Boating Directive or the American ABYC standards for enclosed engine compartments on boats with gasoline engines provide for forced ventilation to extract any accumulated fuel vapors before starting.

The right blower capacity

But to achieve this, it is no use relying on the physical presence of a blower. It also has to be switched on at the right time and run long enough.

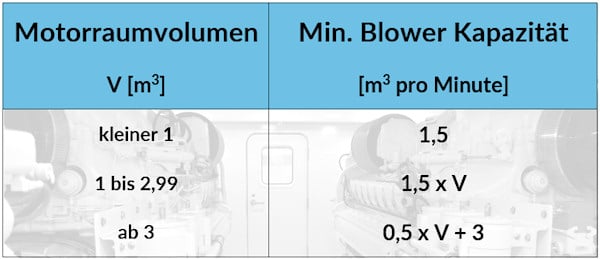

How long depends on the capacity of the blower and the size of the engine compartment. And as far as the former is concerned, the ISO 11105 standard provides very clear guidelines:

For example: if the net engine compartment volume (i.e. the total volume minus the volume of fixed installations) is up to 1 cubic meter, a blower capacity of 1.5 cubic meters per minute or 90,000 liters per hour (1.5x1000x60) is provided.

If you follow the general recommendation of 4 minutes blower run time in the above example, this means that the volume contained in it has been converted at least 6 times. It is best to take a look at the operating instructions for your boat to find out the manufacturer’s specifications.

The right blower installation

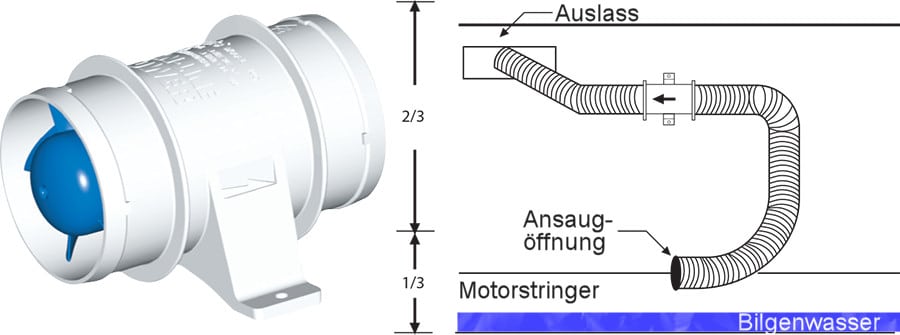

Another important point to ensure the proper functioning of the blower is the routing of the intake line. As fuel vapors are heavier than air and therefore tend to collect near the ground, the intake opening should always be located in the lower third of the engine compartment to ensure maximum efficiency.

![]() ATTENTION! The flow direction of the fan must always be directed outboard!

ATTENTION! The flow direction of the fan must always be directed outboard!

…

What to look out for when buying a blower

![]() As mentioned above, when buying a blower, you should first of all check whether it meets the capacity requirements in terms of the size of the engine compartment.

As mentioned above, when buying a blower, you should first of all check whether it meets the capacity requirements in terms of the size of the engine compartment.

![]() Also ensure that explosion protection in accordance with ISO 9097 or ISO 8846 is guaranteed.

Also ensure that explosion protection in accordance with ISO 9097 or ISO 8846 is guaranteed.

And above all: don’t forget to switch it on before starting the machine(s)!

Sincerely,

Yours Ing.

Ingolf Schneider, MASc (AssocRINA)

Expert for boats and yachts