Yacht appraisals – Thermography

We make visible

what is hidden from the eye

The use of thermographic imaging techniques has successfully established itself in many areas of industry as part of non-destructive material testing.

After numerous practical tests and trials with various material samples, we have decided to use this technology as a standard procedure for our inspections.

Identification

of laminate damage

Also with active thermography if required

Check

of machines

To check the cooling capacity

Electrical

system

Checking cables and components

Identification of laminate damage

on GRP boats

Like any other material used in yacht building, GRP is also subject to a certain ageing process and is exposed to different environmental influences depending on the area of use.

How well a boat can withstand these influences depends on various factors, such as the quality of the gelcoat, the laminate structure or the resin system used.

Cracks in the gelcoat or poorly installed through-hulls and hatches can cause water to penetrate the laminate, which can lead to delamination and thus weakening of the hull structure.

But even without external influences, every gelcoat or topcoat is porous to a certain extent and thus allows moisture to penetrate.

With the help of a thermal image scan, we can check the hull and superstructure for suspicious anomalies, using active thermography methods if necessary.

Inspection of machinery

and drive train

The engine system is the heart of every yacht and also a crucial safety system on board.

This makes it all the more important to ensure that it is always fully operational.

Clogged seawater filters, porous impellers or corrosion damage to heat exchangers and cooling lines can quickly lead to a reduction in cooling capacity and expensive damage.

In addition, the failure of an engine can also mean the failure or (in the case of twin engines) at least a severe restriction of maneuverability, which can pose a danger to the entire crew, especially in bad weather conditions.

Through a precise thermal analysis of your machine system, we can localize suspicious components and suggest preventive maintenance or repair measures in good time.

Review

of electrical systems

Modern high-performance accumulators undoubtedly have their advantages.

Long stays in the bay are possible even without constant operation of the generator and the fridges reliably supply refreshing drinks.

At the same time, however, charging and battery management systems are becoming increasingly complex and can also pose an increased fire risk if not properly maintained.

In older boats, corroded cables or connectors are also regularly found, which also represent a potential damage or latent safety risk that should not be underestimated.

Regular thermographic inspections of electrical systems can localize any overheating problems and prevent potential problems.

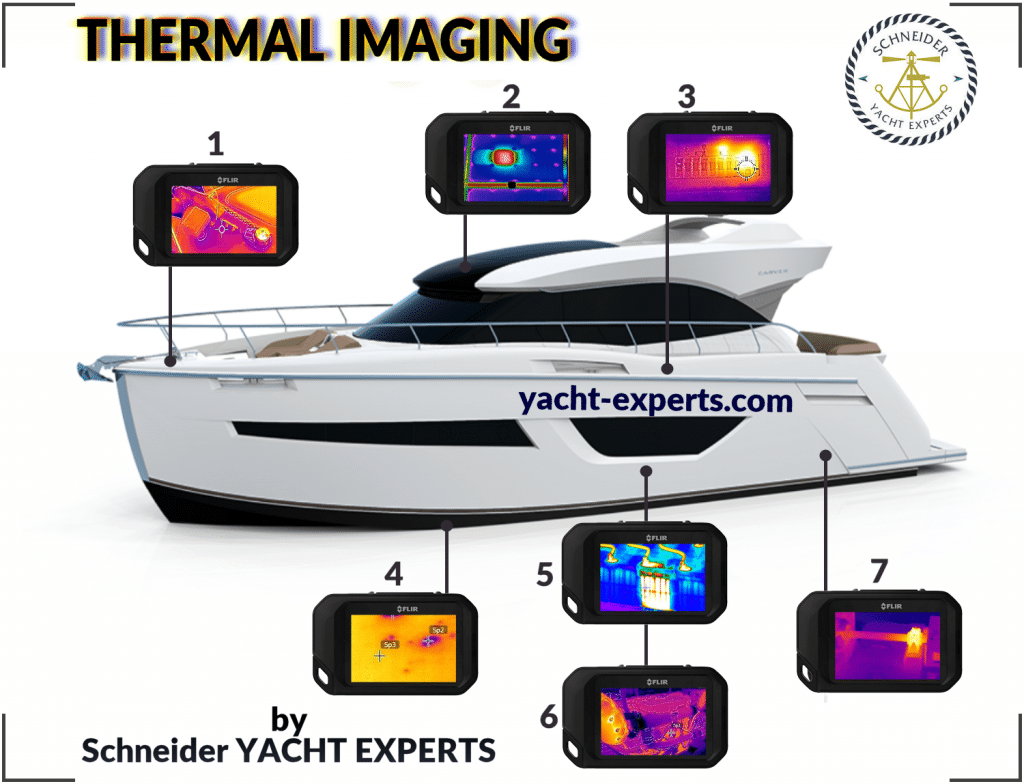

Thermography for yacht appraisals

Application examples

Identification of laminate damage

Soaked sandwich core in the area of the anchor box

Electrical system: Solar panels

Defective cell on a solar panel

220 V shore power system

Overheating on an RCD

Osmosis inspection

Identification of osmosis damage using active thermography*

DC on-board system

Overheating on a consumer battery

Machine system

Testing the engine and exhaust system

Drive train

Overheating on a shaft bearing

*The use of active thermography methods is not part of standard reports and can only be calculated on an individual or order-related basis due to the high effort involved.

The fastest way to your personal quote

With our online inquiry form, you can easily and conveniently obtain your personal quote for a pre purchase yacht survey.

Simply enter the boat data and the berth and select the desired scope of the inspection.

We will then send you a binding offer within 2 working days, including any travel expenses.