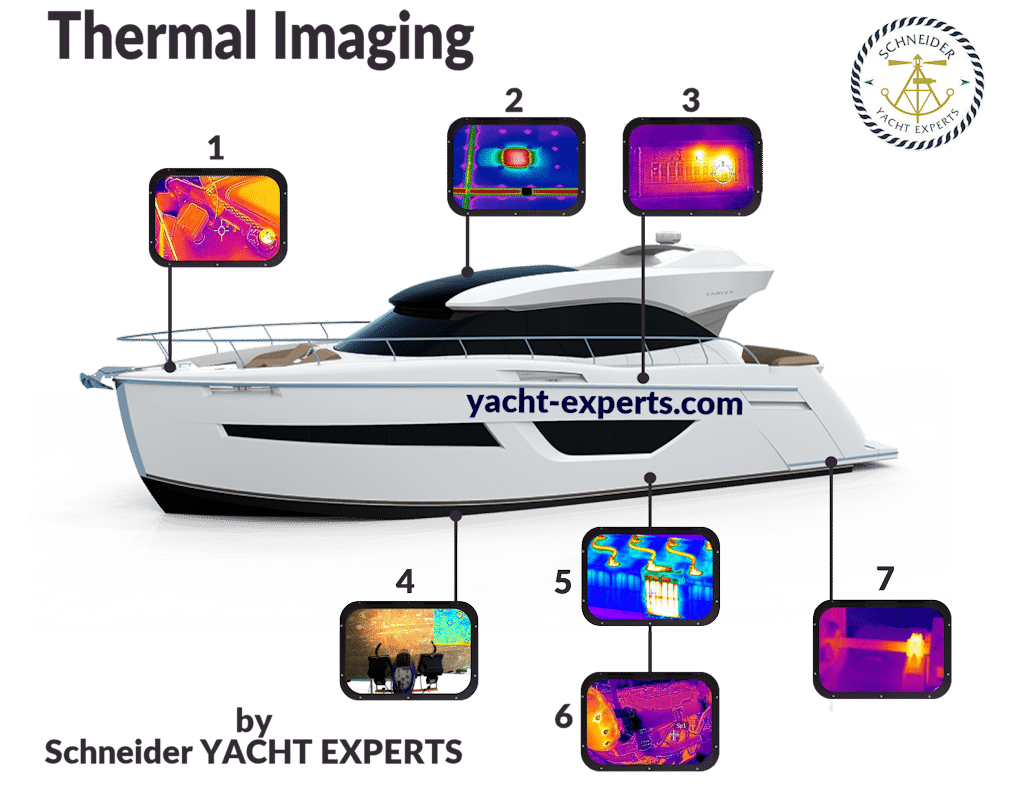

Yacht Surveys – Thermal Imaging

HIGH DEFINITION

INFRARED SCANS

The use of thermographic imaging techniques has successfully established itself in the context of non-destructive material testing in many areas of industry.

After numerous practical tests and trials with various material samples, we decided to use this technology as a standard procedure in the course of our inspections.

Identification of

Laminate Defects

Engine and Drivetrain

Inspection

Electric

Systems

IDENTIFICATION OF LAMINATE DEFECTS

ON FIBERGLASS BOATS

Cracks in the gelcoat or poorly installed through-hull fittings and hatches can cause water to penetrate the laminate, which can lead to delamination and weakening of the hull structure. But even without external influences, every gelcoat or top coat is porous to a certain extent and thus allows moisture to penetrate.

Special mention should also be made of boats with outboard motors, which regularly have significant transom damage due to improper mounting of the motor, in which the core structure of the laminate is often irreparably destroyed and only expensive complete renovations are possible as a repair measure.

With the help of a thermal image scan, we can check the hull and superstructure for suspicious anomalies, whereby active thermographic methods are also used.

INSPECTION OF ENGINE

AND DRIVETRAIN COMPONENTS

The engine system is the heart of every yacht and at the same time a crucial safety system on board. It is all the more important to always ensure that their full operational capability is guaranteed. Clogged seawater filters, porous impellers or corrosion damage to heat exchangers and cooling lines can quickly lead to a reduction in cooling performance and costly damage.

In addition, the failure of an engine can also mean the failure or (in the case of twin engines) at least a severe restriction in maneuverability, which can be a danger for the entire crew, especially in bad weather conditions.

With a precise thermal analysis of your machine system, we can localize suspicious components and suggest preventive maintenance and repair measures in good time.

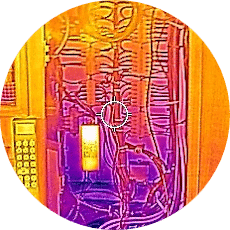

INSPECTION OF

ELECTRIC INSTALLATIONS

Modern high-performance accumulators undoubtedly have their advantages.

Long stays in the bay are possible without constant operation of the generator and the fridges reliably deliver refreshing drinks. At the same time, however, charging and battery management systems are becoming more and more complex and, if poorly maintained, can sometimes also represent an increased risk of fire.

In older boats there are also regularly corroded cables or connectors, which also represent a potential for damage or a latent safety risk that should not be underestimated.

Regular thermographic checks of the electrical systems can localize any overheating problems and avoid potential problems.

THERMOGRAPHY FOR YACHT SURVEYS

APPLICATION EXAMPLES

Identification of a Laminate Defect

Electric System: Solar Panels

AC Shore Power System

Osmoses Inspection

DC Electric System

Engine Installations

Drivetrain

Simply calculate the costs for your pre purchase yacht survey online